-

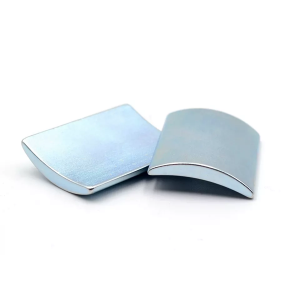

Customized Neodymium Permanent Magnet Special shape Strong Magnet

Our Services:

- Factory direct sale,FCL or LCL is welcome.

- .Small order & trail order is available.

- OEM is supported.

- Third party inspection is accepted.

-

Neodymium Magnet Special Shape Rare Earth Magnet

Neodymium Magnet Special Shape

Special size can be cusomized according to your requirements.Lead Time:

5-7 days for samples;

10-15 days for mass production.Direction of Magnetization:Can be magnetized Diametrically, through Width or Thickness.Maximum extent of magnetization is 60mm. -

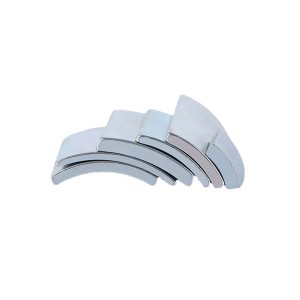

Motor Magnet Arc Magnet Neodymium powful Magnet

Magnet Coating Types :

Support all magnet plating , like Ni, Zn, Epoxy , Gold, Silver etc.

Ni Plating Maget:

Good anti-oxidation effect, high gloss apprearance,long servie life .

Zn Plating Magnet:Suitable for general requirements on surface appearance and oxidation resistance .Epoxy Plating Magnet:Black surface, suitable for harsh atmospheric environments and occasions which require high

corrosionresistance. -

Arc Shape Neodymium Magnet Motor Magnet N50 N52

Grades of Neodymium Magnet

Neodymium magnets are all graded by the material they are made of. As a very general rule, the higher the grade (the number

following the ‘N’), the stronger the magnet. The highest grade of neodymium magnet currently available is N52. Any letter

following the grade refers to the temperature rating of the magnet. If there are no letters following the grade, then the magnet

is standard temperature neodymium. The temperature ratings are standard (no designation) – M – H – SH – UH – EH. -

Rare Earth Permanent Magnet Powerful Disc Magnets Customized size

Grades of Neodymium Magnet

Neodymium magnets are all graded by the material they are made of. As a very general rule, the higher the grade (the number

following the ‘N’), the stronger the magnet. The highest grade of neodymium magnet currently available is N52. Any letter

following the grade refers to the temperature rating of the magnet. If there are no letters following the grade, then the magnet

is standard temperature neodymium. The temperature ratings are standard (no designation) – M – H – SH – UH – EH.

-

Super Strong Neodymium Magnet Ni Coating Permanent Magnet

Speciation for Radial magnetization Neodymium Disc magnet:

1. Grade: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

2. Maximum Working temperature: 60°C to 200°C Neodymium NdFeB Disc Magnet with countersunk hole

3. Shape: Arc, Block, Bar, Ring, Cube, Disc, or others.

4. Application: Computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave communication, petrochemical industry, medical apparatus and equipment

-

Arc shape Motor Magnets Neodymium Magnets Zinc coating

Customized Neodymium Magnets:

1. Grade: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH and 30EH-35EH;

2. Maximum Working temperature: 60°C to 200°C Neodymium NdFeB Disc Magnet with countersunk hole

3. Shape: Arc, Block, Bar, Ring, Cube, Disc, or others.

4. Application: Computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave communication, petrochemical industry, medical apparatus and equipment.

-

Disc Magnet Neodymiun strong Magnet Ni coating

Application:

Computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave communication, petrochemical industry, medical apparatus and equipment,etc.

-

Super Strong N52 Neodymium Magnet Nickel-coating Disc Magnet

Neodymium( NdFeB )magnets are the type of rare earth magnet commercially available and are manufactured in a wide range of shapes, sizes and grades. Hesheng Magnetics Co.,Ltd. is the role -model enterprise among magnets manufacturing industries in China. We own onestep complete industrial chain from raw material blank, cutting, electroplating and standard packing.

-

N35 50×30 Neodymium Magnet rare earth magnet super strong disc

Neodymium Permanent Magnet

Neodymium( NdFeB )magnets are the type of rare earth magnet commercially availableand are manufactured in a wide range of shapes,sizes and grades.

Hesheng Magnetics Co., Ltd. , are a professional magnet manufacturer,

we ownone-step complete industrial chain from raw material blank, cutting, electroplating and standard packing. Neodymium Permanent

Magnet can be customized according to your requirment.

Over several decades Experience Neodymium Magnet Manufacturer

100% Satisfaction Guaranteed On Quality

Samples and Trial Orders Are Most Welcome! -

Neodymium Iron Boron Super Strength Magnets round shape

These super strength magnets provide you with countless possibilities as they are ideal for various purposes. Use them in order to Hang Heavy Objects And Complete Educational, Science, Home Improvement And DIY Projects ,They also are great for industrial application.

-

N35 N38 N40 N42 N48 N52 Strong neodymium magnet

We accept customized services:

1) Shape and Dimension Requirements

2) Material and coating requirements

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)