Product Parameter

| Product Name: | Neodymium Magnet, NdFeB Magnet | |

| Material: | Neodymium Iron Boron | |

| Grade & Working Temperature | Grade | Working Temperature |

| N30-N55 | +80℃ | |

| N30M-N52M | +100℃ | |

| N30H-N52H | +120℃ | |

| N30SH-N50SH | +150℃ | |

| N25UH-N50UH | +180℃ | |

| N28EH-N48EH | +200℃ | |

| N28AH-N45AH | +220℃ | |

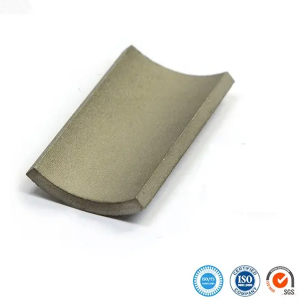

| Shape | Disc, Cylinder, Block, Ring, Countersunk, Segment, Trapezoid and Irregular shapes and more. Customized shapes are available | |

| Coating | Ni, Zn, Au, Ag, Epoxy, Passivated, etc.. | |

| Application | Sensors, motors, filter automobiles, magnetic holders, loudspeakers, wind generators, medical equipment, etc. | |

| Sample | If in stock, free sample and deliver at same day; Out of stock, delivery time is same with mass production | |

Product Description

The surface of NdFeB takes appropriate and suitable surface treatment, NdFeB is a multi-phase structure, the potential difference of different phases is large, causing the magnet itself to become potential battery, acidic environment is to accelerate its corrosion; Passivation treatment for ndfeb surface, passivation process is simple, easy to control, the surface of the formation of dense passivation film can strengthen the corrosion resistance.

Due to the corrosion resistance of sintered ndfeb itself is not good, so in the general case produced products must have a coating protection, according to the requirements of product applications against corrosion by far the most widely used environment demand against corrosion, currently the most widely has the following coating: galvanized, nickel plated, epoxy resin, chemical plating, gold-plated, silver, aluminum plating, chrome plating, and a small amount of gonadorelin coating.

Why Choose Us

1. 30 Years Magnet Factory

60000m3 workshop, more than 500 employees, as many as 50 technical engineers, one of the leading enterprises in the industry.

2. Customization Services

Customized size, gauss value, logo, packing, pattern, etc..

3. Cheap Price

The most advanced production technology ensures the best price. We promise that under the same quality, our price is definitely the first echelon!

Our Services

1.Factory direct sale,FCL or LCL is welcome.

2..Small order & trail order is available.

3.OEM is supported.

4.Third party inspection is accepted.

FAQ

Q2. What about the lead time?

A:Sample needs 10-15 days, mass production time needs 10-25days for order quantity more than.

Q3. Do you have any MOQ limit for magnet order?

A: Low MOQ, sample order is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 10-15 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order for magnet?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on magnet product or package?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.